Global EPS Recycling Map

The EPS industry supports recycling in more than 50 countries. Numerous recycling solutions, including mechanical, chemical, microwave and other processing technologies ensure a strong foundation for consistent growth.

See how EPS is being recycled in various global regions by downloading this map.

EPS Recycling Initiatives – Australia

StyroCycle, an Australian initiative of Expanded Polystyrene Australia (EPSA) dedicated to transforming discarded EPS materials into valuable resources, contributes to the circular economy and ensuring a closed loop of EPS for consumers in Australia. It is just one of many programs across the globe working towards EPS recycling sustainability.

StyroCycle supports the key priorities identified in the 2018 Expanded Polystyrene Report and the APCO Collective Impact Report.

EPS Sustainable Manufacturing

EPS manufacturing uses resources such as water and raw materials – 2% polystyrene from fossil sources or from recycled EPS – efficiently in production. The steam consumed in the EPS manufacturing process is then condensed back to liquid water and is reused many times over in the EPS production process.

Innovations in manufacturing technologies ensure EPS production minimizes energy consumption with mold cavities that cool more quickly and processes that recycle water and recapture air emissions. Newer manufacturing processes use radio frequency instead of steam to mold EPS.

Global Product Distribution with EPS

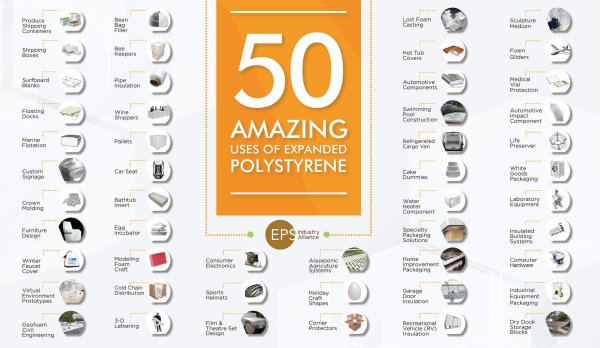

EPS provides effective, safe, and secure protective packaging for consumer goods — there is no substitute for expanded polystyrene in harsh distribution environments when transporting essential pharmaceuticals, fresh food and other valuable goods.

EPS offers incredible physical properties that make it an ideal material choice in hundreds of applications.

Growing New Ideas

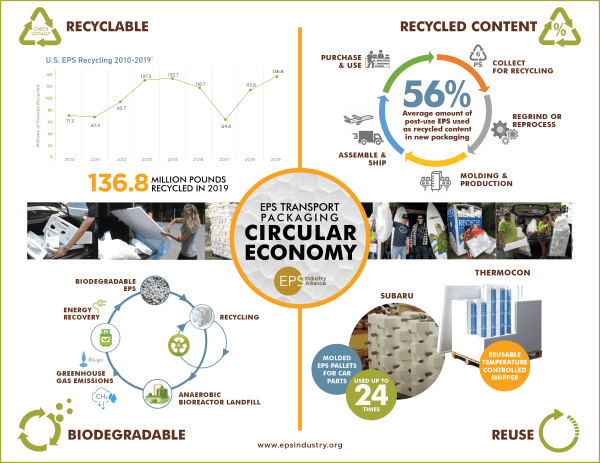

EPS is recyclable. EPS saves energy. EPS saves resources. GESA members are vested in product stewardship that supports a circular economy, thriving on innovation to support ecological advantages. Versatile, reliable and available in a wide range of applications, EPS ensures safe transportation of the things we value and delivers maximum comfort and efficiency at home and work. The EPS industry is constantly working on new approaches to improving its protection, its recyclability and its insulation properties even more.